Chapter 1

The value chain for carbon capture and storage (CCS)

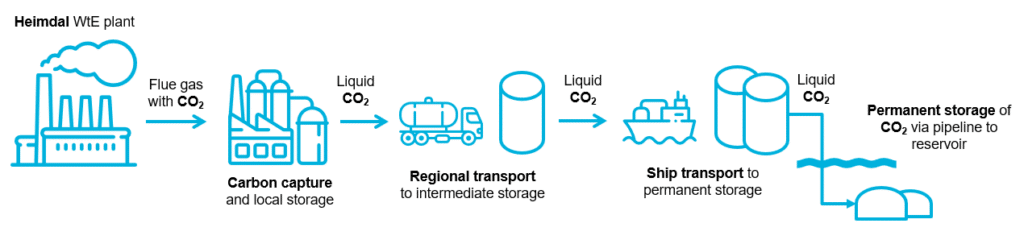

The CCS value chain contains a group of complementary technologies that help prevent CO2 from waste incineration from ending up in the atmosphere. Here, the CO2 is captured, liquefied, and transported to storage. In most cases, an intermediate storage will also be needed. Below are the various steps in the value chain briefly described with reference to the pages in this manual where it says more about this.

Pre-treatment of the flue gas - Capture and liquefaction of CO2 - Transport to intermediate storage - Intermediate storage and terminal for shipment of CO2 - Ships - Storage of CO22

The first step in the CCS value chain is mapping the flue gas.

A thorough mapping of the flue gas composition under different operating conditions is important, as this can guide the choice of material in the next phase, when the CO2 is to be captured.

Before capture, the flue gas temperature must be reduced to around 50 degrees, which means that large condensing heat exchangers are needed. There may also be a need to make upgrades or introduce new cleaning steps in the smoke gas cleaning system to meet the requirements of flue gas composition from a capture plant.

Capture and liquefaction of CO2

There are several different technologies, at different levels of maturity. These are described in chapter 2.

Good integrations between the CO2 capture plant and the waste fuel plant are also important to put in place.

Note: A capture plant requires area, energy, cooling water systems, etc., and in most cases the CO2 must be conditioned before it can be transported to storage. For smaller volumes this requires compression and for liquefaction, as well as an small local storage.

Transport of the captured CO2 from the capture plant to intermediate storage.

The distance from the capture plant to the intermediate storage will determine where the CO2 should be transported.

Transport of liquid CO2 by truck is the solution that the projects of the partners in KAN have seen as most appropriate.

Transport og mellomlager-løsninger er nærmere beskrevet i kapittel 4. Der er det også gitt indikasjoner på hva transport av CO2-en og anlegg for mellomlagring kan koste.

The next step in the value chain for CCS is a terminal for CO2 shipment.2

This manual provides indications of costs associated with transport, intermediate storage and terminal for shipment. The basis for this is a CCS plant with a capacity from 100,000-200,000 tons of CO2 annually and a hypothetical location from intermediate storage 10-20 km away from the CCS plant.

Costs such as geographical location, property, ground works, quay facilities, infrastructure such as roads, water, sewerage, etc. are not included in the cost calculations in this manual, but important to clarify early.

The next step is transport of CO2 from quay to permanent storage via ship.

The size of the ship, availability of ships of optimal size, distance from intermediate storage to permanent storage and frequency of call for the ship are factors that are important to clarify early.

A lot of technology development is underway to be able to scale up volumes and to reduce costs.

The final step in the CCS value chain is final storage of the CO2, and this must be done safely.

Today, it seems most relevant to store CO2 in suitable formations under the seabed.

In chapter 5 The chapter deals with storage sites that will be operational in the period 2028 – 2030.