Chapter 3

Other measures for the use of waste heat

Chapter 3

The heat from "KAN Referansa" is approx. 55 °C, it is difficult to use this for purposes other than heating. For waste incineration plants connected to an DH network, it is reasonable to assume that most industries/consumers of heat in the immediate vicinity will be connected to the same DH network. In other words, it is very challenging to use the waste heat from the capture plant beyond the DH network.

Waste heat of 80°C and higher can be used in an Organic Rankine Cycle (ORC) turbine for power generation, as the waste heat from the "KAN Referansa" is intended to be 55°C this is not worth investigating in the first place. If a capture supplier supplies waste heat of approx. 80 °C, it should be investigated whether this can be utilized in an ORC turbine.

9.1 Accumulator for short-term DH variations

During the summer season, the heat demand in the district heating network is low, and in most cases, there will be sufficient heat available from the incineration plant to cover both the capture plant and the DH network's heat needs. During summer, it is therefore not necessary to recover the waste heat from the capture plant with heat pumps for the district heating system. As the outside temperature begins to drop, the remote heating network's heating demand will begin to increase. Short and eventually longer periods will then occur where the heat demand exceeds the capacity of the energy recovery plant, as shown in Figures 7 and 8.

To even out the short-term variations, heat can be accumulated in periods with surplus for use in periods when the need exceeds the plant capacity. This can be achieved in several ways:

- Accumulation in the district heating supply system. This is done by increasing the temperature of district heating out of the central energy plant to district heating customers up to the maximum design temperature of the district heating network. The increased temperature represents a stored amount of energy that can be used to even out power peaks.

- Accumulation in both supply and return system. As accumulation in turn, however, a greater amount of energy can be stored by allowing increased temperature in the return system. One disadvantage of this measure is that increased return temperature will negatively affect the possibility of direct exchange with a carbon capture plant.

- Accumulator tank. Installation of an accumulation tank will be able to replace or complement accumulation in the district heating network and will provide greater capacity to even out the daily variations. Such an accumulator tank will, for example, help reduce partial load operation on any heat-recovering heat pumps and ensure fewer starts/stops and better system performance. Statkraft in Trondheim has installed such a tank as shown in figure 66.

If smart integrations with the use of heat pumps to collect waste heat from the carbon capture plant to the district heating system are considered, an assessment of the possibility of accumulation should be key. Responsible for the district heating system itself should be involved in such assessments.

9.1.1 Other measures for short-term DH variations

To take care of the short-term daily variations in the DH grid shown in Figures 7 and 8, one can also set the heat pump as a base load in the system and rather vary the heat from the turbine steam for use in the DH network. The turbine steam can then be cooled in existing dry coolers on the roof, which can be regulated quickly. This is an option if you don't have the possibility of short-term accumulation as mentioned above.

From an energy-economy point of view, this is less profitable as the heat pumps have a power consumption, by making HPs as base load you get a continuous power consumption. This ensures that the heat pumps operate more smoothly by not having to start and stop too often. Frequent start-ups of heat pumps reduce the technical lifetime of heat pumps, especially those of compressors. The heat pumps only need to be base load at intervals. This can be done based on future weather forecasts and predictive analyses of DH needs.

This will be a cost-benefit analysis of the investment costs for accumulation capacity and increased operating costs of loading heat pumps. Such an analysis must be done individually for each plant.

9.2 Geothermal seasonal storage

Part of the waste heat from a carbon capture plant can be a good source of heat for a large-scale geo-thermal seasonal storage. The establishment of such a thermos/well park could then potentially be used to cool parts, or all of the capture plant. Furthermore, heat pumps can use the well park as a heat source for operating the heating system.

This is being studied/built in connection with the waste incineration plants in Oslo and Tromsø. This is most relevant where it is expected that the need for DH will increase in the future. This must be assessed in relation to the increased DH delivery in subchapter 7.7.3, and the need to increase it further.

9.3 New external heat source

An alternative to the above proposed smart integrations could be to accept reduced power delivery to district heating from the waste incineration plant and replace lost heat deliveries from another energy source elsewhere in the district heating system. This can be, for example:

- Already installed capacity in other intermediate and peak load centers

- Electric boilers

- Bioenergy/return chips, etc.

In particular, waste incineration plants with low energy utilization and therefore little “lost energy” for district heating when installing a carbon capture plant, should consider the cost/benefit of using an external heat source other than relatively expensive heat pumps and integrations between the carbon capture plant and the district heating system.

It is also worth investigating for DH networks that are connected to larger industrial players whether any of them can increase their DH supply to compensate for the DH delivery lost.

9.4 Potential consumers of waste heat outside the "KAN Reference"

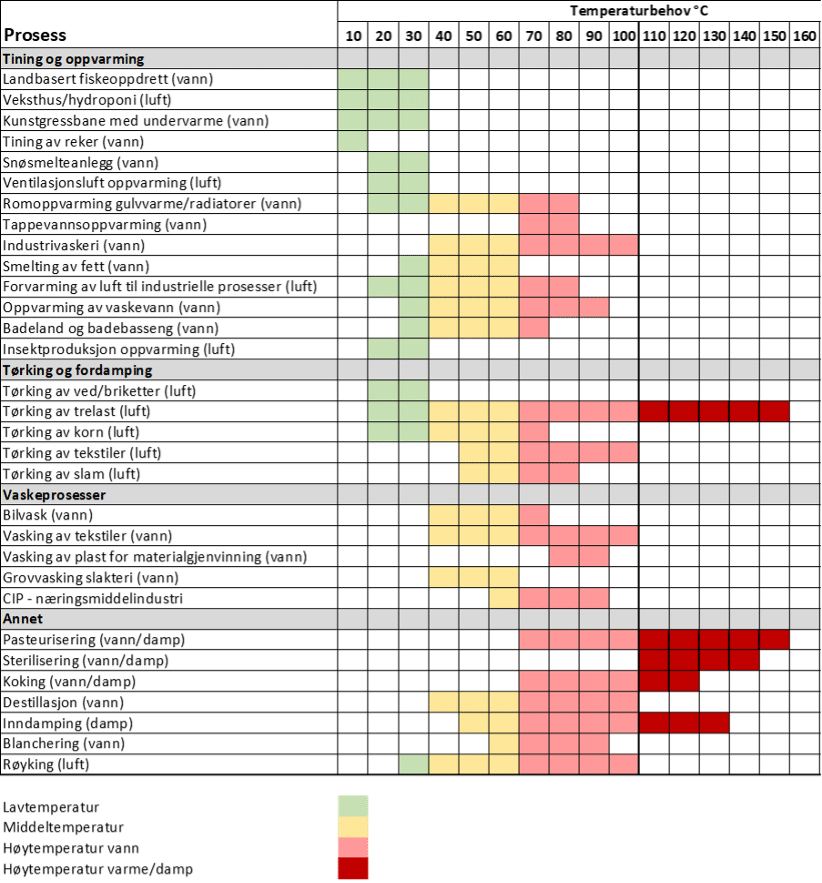

It is worth examining the surrounding processes and enterprises and their eventual need for waste heat at a lower temperature. There are many processes that need heat at lower temperatures, a handful of them, with their approximate temperature levels are shown in Table 4. The heat from the "KAN Referansa" will be available at approx. 55 °C.

It may be useful to find out about surrounding industries, the list in Table 4 does not cover all industries that need heat at lower temperatures. It may also be a good idea to find out about future plans for companies and potential business parks under development and fully developed in the area.

9.5 Solvent storage

SINTEF has carried out a study to look at the potential of storing the amine solvent saturated with CO2 in times when the DH network has high demand and rather regenerate solvent times when DH demand is low and there is more heat available from turbine capacitor. The study investigated the possibilities of solvent storage over a day. This reduced the amount of waste heat that needs to be cooled to the atmosphere over a year by 21.5% (mainly in winter when it could be aligned with DH demand). This is done with two tanks, one with saturated amine-solvent and one with unsaturated amine solvent. This tanker park can be located at a different location, if necessary, but the amine solvent must then be pumped to the tank park. The 'Energy Utilization Factor', defined as the rate between total energy output from the WtE plant (both thermal and electrical) over total thermal input to the capture plant, increases by 1%.

SINTEF plans to expand this study to a seasonal study. This possibility is not something that catch suppliers have standardized inside, but rather something that must be agreed and developed in consultation with catch suppliers if applicable.